Jagdamba Spinning Mills Limited

Renowned and recognized for introducing innovation in processing, developing and manufacturing fiber-based yarn products, Jagdamba Spinning Mills Ltd. is Nepal’s leading yarn manufacturer. Our mill utilizes advanced production technologies coupled with a flexible production facility that allows us to produce 100% polyester yarn, polyester viscose blended yarn, and acrylic yarn - all at various counts.

Our products meet European & International textile standards and are continually checked for consistent quality. Whatever your needs may be, our yarn is guaranteed to meet them. Additional detail regarding our products, machinery & equipment, and process is also available.

Products:

Jagdamba Spinning Mills Ltd. is equipped to produce premium quality. Yarn ranging from 8s NE to 40s NE (Single and Various), plied, polyester & polyester/viscose (Raw-White or Black).

For more details, see table below.

POLYESTER | PV 65/35 PV | PV 70/30 | PV 90/10 | Acrylic Yarn |

8/1 PES | 8/1 PV 65/35 | 8/1 PV 70/30 | 8/1 PV 90/10 | 3/16 ACRYLIC |

8/2 PES | 8/2 PV 65/35 | 8/2 PV 70/30 | 8/2 PV 90/10 | 4/16 ACRYLIC |

8/3 PES | 9/1 PV 65/35 | 9/1 PV 70/30 | 9/1 PV 90/10 | 1/23 ACRYLIC |

8/4 PES | 10/1 PV 65/35 | 10/1 PV 70/30 | 10/1 PV 90/10 | 2/23 ACRYLIC |

9/1 PES | 10/2 PV 65/35 | 10/2 PV 70/30 | 10/2 PV 90/10 | |

10/1 PES | 10/3 PV 65/35 | 10/3 PV 70/30 | 10/3 PV 90/10 | |

10/2 PES | 10/4 PV 65/35 | 10/4 PV 70/30 | 10/4 PV 90/10 | |

10/3 PES | 11/1 PV 65/35 | 11/1 PV 70/30 | 11/1 PV 90/10 | |

10/4 PES | 12/1 PV 65/35 | 12/1 PV 70/30 | 12/1 PV 90/10 | |

11/1 PES | 12/2 PV 65/35 | 12/2 PV 70/30 | 12/2 PV 90/10 | |

12/1 PES | 12/3 PV 65/35 | 12/3 PV 70/30 | 12/3 PV 90/10 | |

12/2 PES | 14/1 PV 65/35 | 14/1 PV 70/30 | 14/1 PV 90/10 | |

12/3 PES | 15/1 PV 65/35 | 15/1 PV 70/30 | 15/1 PV 90/10 | |

14/1 PES | 15/2 PV 65/35 | 15/2 PV 70/30 | 15/2 PV 90/10 | |

15/1 PES | 15/2 PV 65/35 | 15/3 PV 70/30 | 15/3 PV 90/10 | |

15/2 PES | 17/1 PV 65/35 | 17/1 PV 70/30 | 17/1 PV 90/10 | |

15/3 PES | 17/2 PV 65/35 | 17/2 PV 70/30 | 17/2 PV 90/10 | |

17/1 PES | 20/1 PV 65/35 | 20/1 PV 70/30 | 20/1 PV 90/10 | |

17/2 PES | 20/2 PV 65/35 | 20/2 PV 70/30 | 20/2 PV 90/10 | |

20/1 PES | 24/1 PV 65/35 | 24/1 PV 70/30 | 24/1 PV 90/10 | |

20/2 PES | 24/1 PV 65/35 | 24/1 PV 70/30 | 24/1 PV 90/10 | |

20/2 PES | 24/2 PV 65/35 | 24/2 PV 70/30 | 24/2 PV 90/10 | |

24/1 PES | 28/1 PV 65/35 | 28/1 PV 70/30 | 28/1 PV 90/10 | |

24/2 PES | 28/2 PV 65/35 | 28/2 PV 70/30 | 28/2 PV 90/10 | |

28/1 PES | 30/1 PV 65/35 | 30/1 PV 70/30 | 30/1 PV 90/10 | |

28/2 PES | 30/2 PV 65/35 | 30/2 PV 70/30 | 30/2 PV 90/10 | |

30/1 PES | 40/1 PV 65/35 | 40/1 PV 70/30 | 40/1 PV 90/10 | |

30/2 PES | 40/2 PV 65/35 | 40/2 PV 70/30 | 40/2 PV 90/10 | |

40/1 PES | ||||

40/2 PES |

|

Machinery & Equipment:

Production Machinery:

- B/ROOM – AND Blender – LMW Make, India.5 line with capacity 500kgs/hrs each

Condenser:

- 36 nos of Cards – LC300AV3 – LMW, India. with capacity1100kgs/day each.

- 12 nos of DO/6 Draw Frame – LMW, India with capacity 3500kg/day each

- 10nos of RSB Draw Frame – LMW, India with capacity 3400kg/day each

- 11 nos of LFS1660, LF4200A – LMW, India speed frame with capacity 2800kgs/day each

- 39 nos of Ring Frame (720 spindles each ) LR6/S – LMW, India with capacity 800kg/ per day each

- 13 nos of Autoconer (AC 5, x5 and 338)– Schlafhorst, Germany with capacity 2400kgs/day each

- 6 nos of Parallel Winding – SaurerPeass, India with capacity 2268kgs/day each

- 28 nos of Two For One Twister (TFO) JV150 – India with capacity 525kgs/day each

Additional Equipment:

- LUWA Humidification Plant – Switzerland.

- USTER TESTERS, For Testing - Switzerland.

- Blend Testing Machine – India.

- Kay And Cone Export For Online Checking And Testing.

- Other Testing Equipment In Lab.

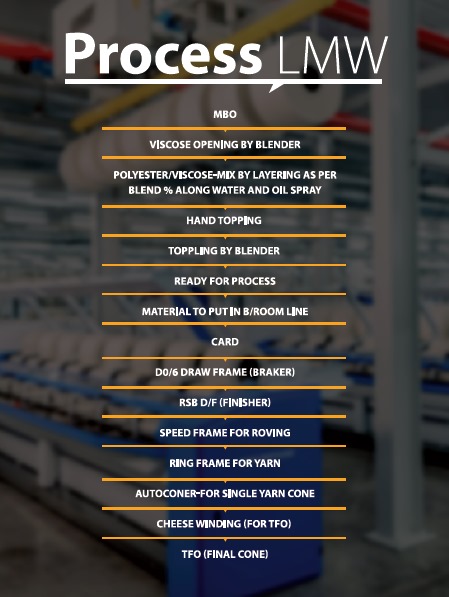

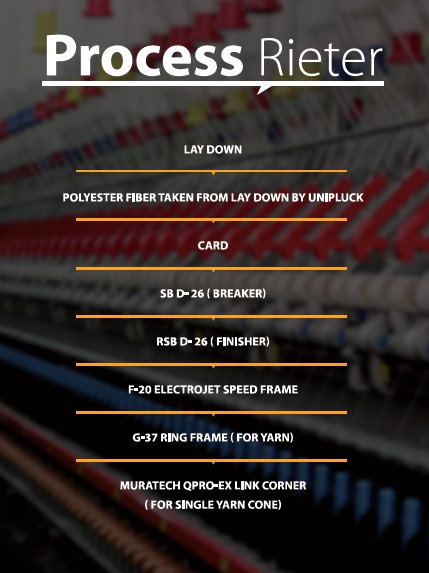

Manufacturing Process:

Capacity:

Selling Market: